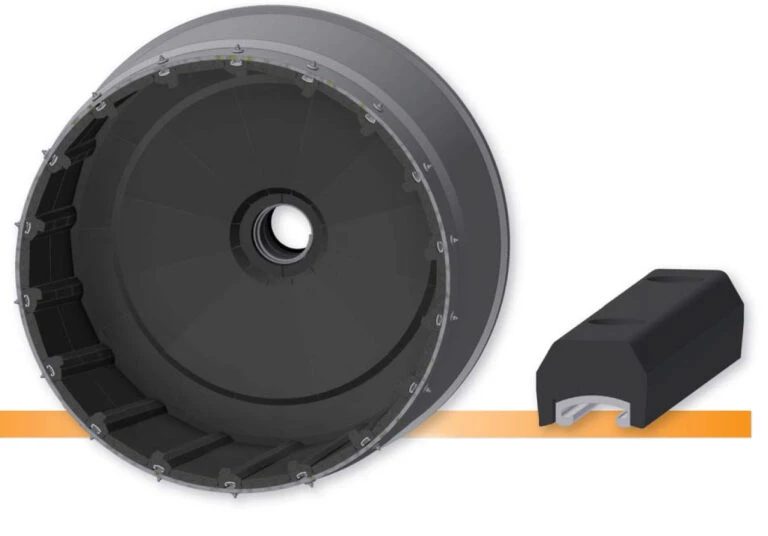

Wear-resistant linings of mills

Rubber linings for ball and cylinder mills produced by ZAM Kęty Sp. z o.o., are widely used in mechanical plants for the processing of ores, non-ferrous metals and in the ceramic and construction industries.

The above-mentioned linings are used with excellent operating results at home and abroad.

Młyn kulowy - widok poglądowy

Młyn kulowy - widok poglądowy

Advantages of rubber linings:

- Rubber linings work 2.5 – 3 times longer than other linings

- The weight of the rubber lining is 4 – 5 times less than the weight of steel lining

- Improving the working conditions of technical services – easy replacement of the lining

- Reduction of energy consumption

- Radical noise reduction

The service life is much higher than in the linings used so far, such as: cast steel plates, plastic plates (eg EPU), basalt cubes, etc. This is achieved through the use of excellent wear-resistant rubber, which has been specially developed for our needs.

Rubber linings work in an open or closed production cycle. In mills with an open production cycle, which are used in the production of porous concrete or sand-lime bricks, we successfully replace the mill partitions by introducing spiral damming thresholds, which results in self-segregation.

Przekrój przez płaszcz walczaka

Przekrój przez płaszcz walczaka

The design support is the in-house construction and technology office with 30 years of experience in the design and production technology of rubber and rubber-metal products. High-class specialists will comprehensively develop documentation of individual products, as well as documentation of entire machines and devices lined with rubber elements made of abrasion-resistant mixtures.

We offer installation at the customer’s.