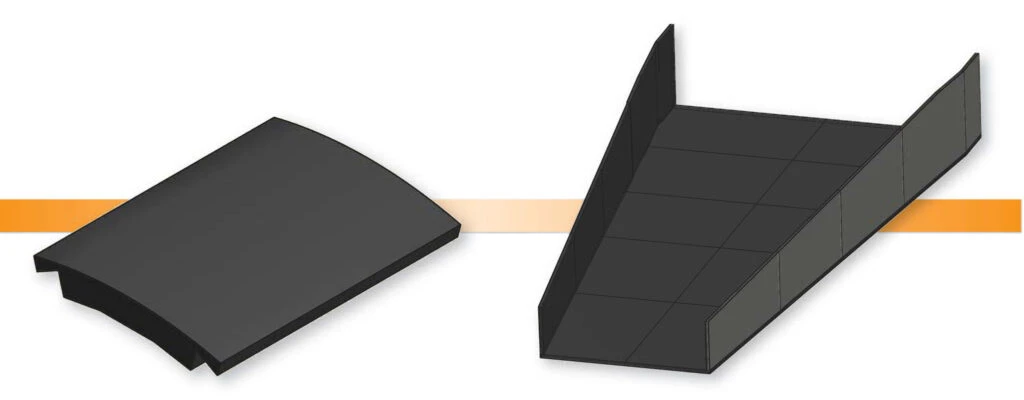

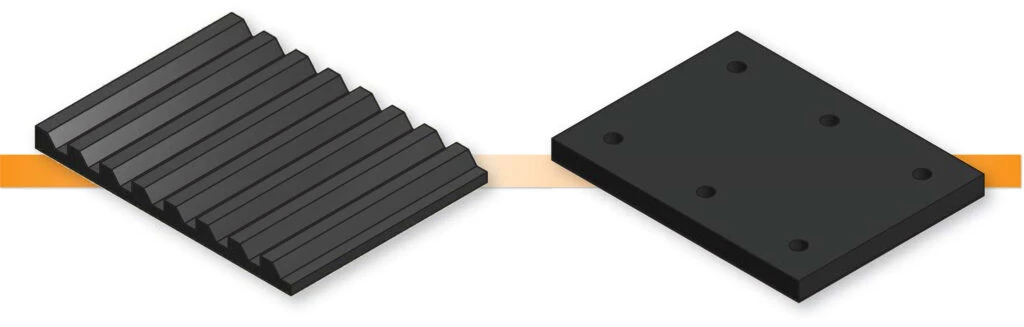

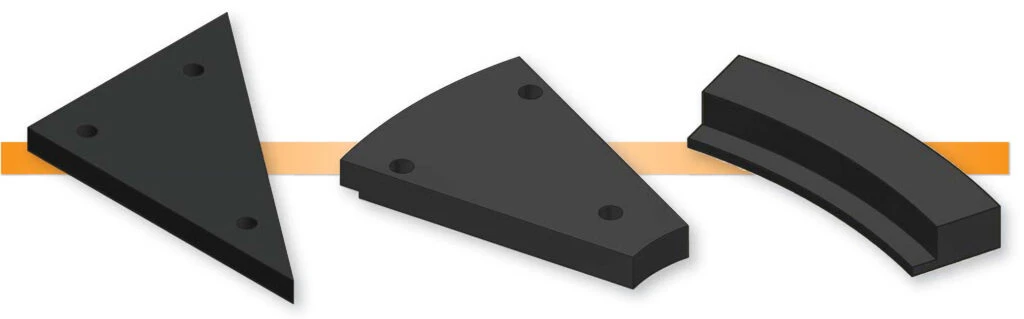

Rubber plates and metal rubber plates

Wear-resistant rubber linings are used in the transport of loose materials (such as sand, coal, coke, ores, minerals, etc.), especially where the transported material rubs the substrate. These are tank walls, chutes, chutes, weight tipplers, walls of devices for cleaning or sandblasting castings. We sell wear-resistant rubber linings to processing plants, metallurgical and mining industries (then we use a hard-wearing, flame-retardant and anti-electrostatic rubber compound).

The main advantages of our solutions:

- Multiple increase of service life in relation to steel linings,

- Reducing the noise level,

- Shock absorption of vibrations caused by falling material,

- Easy assembly and replacement in the event of wear,

- Possibility to use a steel insert for re-covering with rubber after its use,

- Less weight (compared to cast steel linings),

- Significant reduction of operating costs,

- Reducing the possibility of the transport material sticking to the walls.

In addition to continuous production, we specialize in the implementation of atypical, small-lot and unit orders with unique shapes and dimensions.

Rubber Department design support is the in-house construction and technology office with 30 years of experience in the design and production technology of rubber and rubber-metal products. In addition, our specialists assemble wear-resistant floor coverings at customers’ premises.

Locksmithing and welding equipment as well as vulcanization molds are made by the company’s tool division.