Hydrocyclones

In 2016, ZAM Kęty Sp. z o.o. received the gold medal Poznań Fair ITM Poland – Innovations, Technologies, Machines for hydrocyclone – a new type of HC-500/12º ZAM-IMN.

Classifying and thickening hydrocyclones

Solutions applied in manufacturing of classifying and thickening hydrocyclones type HC resulted from 35 years of tests and experience of our Company in close cooperation with the scientists from the Institute of Non-Ferrous Metals in Gliwice. They are applied mainly in mechanical preparation process of mineral raw materials to wet classification in the process of pulverisation, where systems can form in conjunction with crumbling equipment and mechanical classifiers. With our hydrocyclones or batteries of hydrocyclones it is possible to classify suspensions with the limit particle within the scope of 0,0005-0,5 mm and with unit output of hydrocyclones from 20 to 600 m3/ h. They can work separately or in team, known as, in the hydrocyclones’ batteries.

Classification of hydrocyclones due to the sort of lining:

1. Ceramic lining (silicon carbide)

- HC-500/120 ZAM-IMN,

- HC-350/120 ZAM-IMN

In the first quarter of 2015, a tender for the biggest in the Europe modernisation of classification systems for ZWR Lubin, ZWR Polkowice and ZWR Rudna in KGHM Polska Miedź S.A. has been decided. As a result of this decision, ZAM Kęty received an order for production of 58 batteries equipped with 315 items of hydrocyclones type HC-500/120 ZAM-IMN and 48 items of hydrocyclones type HC-350/120 ZAM-IMN. ZAM Kęty will execute the above order in cooperation with IMN Gliwice.

2. Abrasion resistant rubber lining:

- HC-100/100

- HC-200/120

- HC-200/200

- HC-350/120

- HC-350/200

- HC-500/200

- HC-750/300

Application:

Hydrocyclones have found use in industry in the following technologies:

- Classification: Hydrocyclones are used as classifying equipment in mineral raw material enrichment plants, in pulverising systems in order to achieve suitable particle sizes of the material directed for flotation

- Classification and thickening: In wet pulverisation processes, the classifying and thickening hydrocyclones allow to separate minute particles ready for flotation and to thicken rough particles as required by pulverisation process

- Silt and ash removal: Hydrocyclones are used in coal enrichment plants to separate primary silt with the particle size below 0,01 mm prior to flotation or silt and ash removal of post-flotation silt by classification and thickening

- Water draining: Separation and thickening of sand from sandy suspensions in glass-making and moulding sand mines etc

-

In environment protection systems: E.g.:

- Separation of gypsum from neutralisation suspensions in wet flue gas desulfurization systems

- Separation of sand from municipal sewage

- Separation of suspensions from treatment emulsions

- Construction of settling pond embankments from materials contained in suspensions settled in such ponds.

Construction:

Our HC type hydrocyclones are made of segments to provide easy assembly in difficult spatial locations without using heavy equipment. Casing of the hydrocyclone is light steel structure effectively protected against corrosion and fixing elements are galvanised. Inside of the hydrocyclone is lined with replaceable abrasion resistant rubber or ceramic lining (depending on the type of hydrocyclone). Suspension is supplied to the hydrocyclone tangentially to the cylindrical part via rectangular section inlet nozzle. The diameters given in the table below are the alternative diameters resulted from the calculation of the surface of the inlet nozzle section to circular section. It is possible to achieve suitable classification in the wide range of required parameters by the selection of appropriate nozzles. Flanges of inlet and overflow stubs are fitted for typical flange connections.

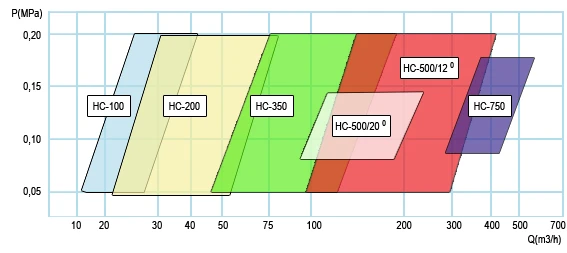

Output:

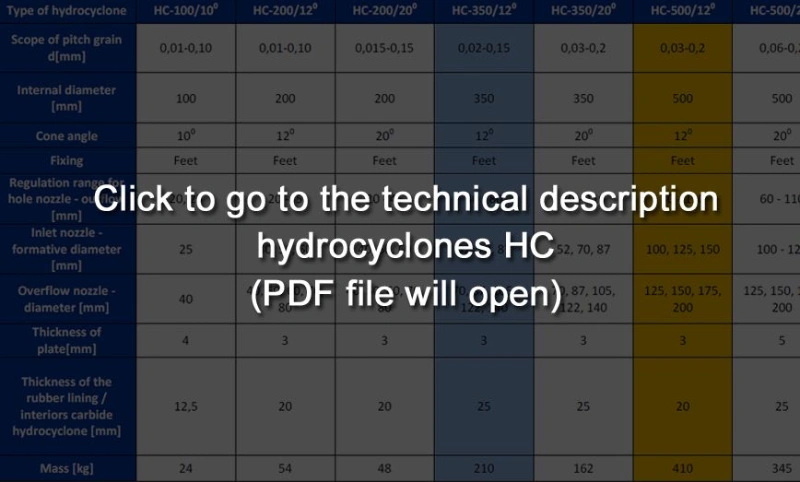

Technical data:

How to order:

We provide free of charge consulting regarding dimensions of single hydrocyclones or batteries. We offer the execution of the start-up.